If you’re relatively new to the pump industry, it may seem difficult on how to select a pump from curve. However, pump selection from curves is not too difficult of a task, as you just need to understand what each of the parameters are. Don’t be ashamed that you don’t know how to select a pump from curve, all of the information is available online at your convenience. We also attempt to do our best in comprehensively covering pump selection to give you the best understanding possible.

February 29, 2024The Inputs You Need For Selecting A Pump

Flow

Flow refers to volumetric flow rate, usually measured in GPM in imperial units or m3/hr (SI).

Total Dynamic Head

Total dynamic head represents head above the discharge flange plus head below the discharge flange, minus losses. Represented in units of ft or meters.

Pump Curves

Pump curves are generated from empirical data, meaning that the curves have been produced from actual testing. For a given hydraulic, combinations of different impeller trim diameters and motor RPMs are tested. The tests of the pump produce head capacity curves, aka pump curves, and is implemented into a pump configuration software. Application Engineers and sales engineers in the pump industry use these to configure pumps based on the customer’s inputs.

Note – If you have curves and don’t want to select a pump yourself, contact a pump company such as Goulds or Flowserve. All you need to do is send them your inputs and data about your set up. Pump companies will determine values like pump length, sump depth, NPSH, etc.

The Parameters You Need To Understand For Your Pump Curve

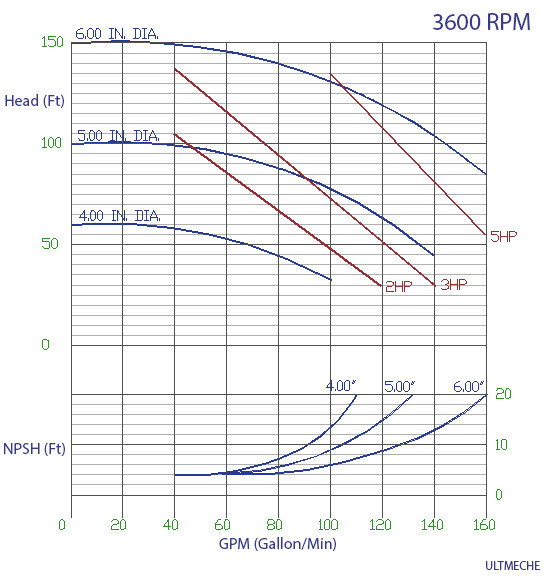

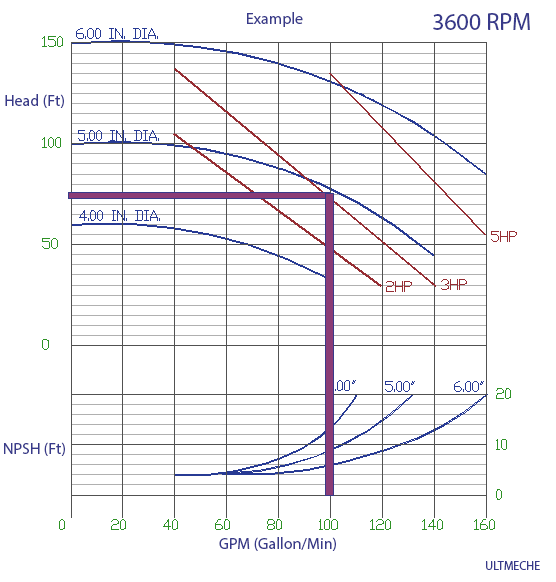

To ensure you understand how to select a pump from curve, you need to understand the parameters you are looking at. From a quick glance at the curve below, we see parameters such as NPSH, RPM, Head, Impeller Diameter, Horsepower. However, there are a few more parameters outside of the ones mentioned when taking into account selection of pumps from curves. The following are the parameters you will need to understand, so that you select the best pump for your hydraulic needs.

Head

The head is the height at which the pump can raise the fluid up, represented in the y-axis of the curve. As mentioned earlier, Head is usually represented in units of feet or meters.

Flow

The volumetric flow rate of the liquid, which is expressed in gallons per minute (GPM) in imperial dimensions. Volumetric flow rate is called out in the x-axis of the pump curve.

NPSH

NPSH refers to Net Positive Suction Head. Net positive suction head is a measurement of pressure required at the pump inlet to avoid pump cavitation. NPSH is denoted in two terms, NPSHa and NPSHr.

NPSHa

The amount of NPSH available at the pump site. This is a physical parameter that is defined by the atmospheric conditions of where the pump will be installed.

NPSHr

The amount of NPSH required for the pump not to cavitate. NPSHr comes from empirical data as a function of testing the specific hydraulic line that we are looking at.

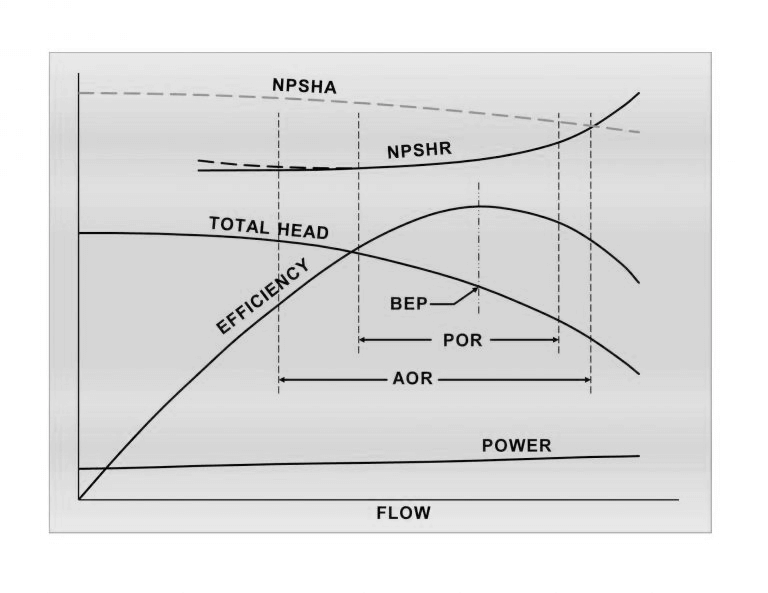

See the curve below for a better visual on how NPSHa and NPSHr should be compared. It is important to have margin between NPSHa and NPSHr to avoid pump cavitation. Avoiding pump cavitation will increase the operating life of the pump, and as a result will be the cheaper option.

Impeller Diameter

The head of your pump will increase as the impeller diameter increases. Within a certain set of hydraulics, you can choose which impeller diameter will suit your needs. Impeller trimming is a common practice in the hydraulics industry, which involves trimming the impeller diameter to get the flow and head required for your operation.

Motor RPM

Different motor RPMs will produce different pump curves. In general, pumps used run the following motor configurations:

- 2 pole, 3600 RPM

- 4 pole, 1800 RPM

- 6 Pole, 1200 RPM

Intuitively, as the RPM changes, pump performance will change. Depending on the hydraulic and pump specific speed we are looking at, we may consider variations in RPM to get the pump curve that we want. The curve above is an example of what is produced at 3600 RPM, at various impeller trim diameters. Expect to see a completely different hydraulic performance when switching motor RPMs.

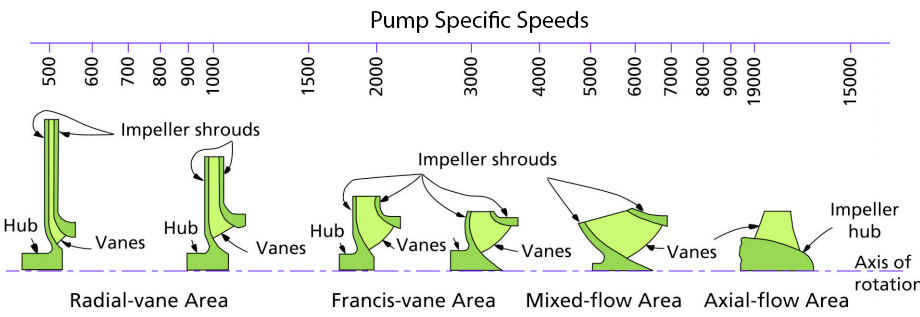

Specific Speed (Ns)

Specific speed is simply a characteristic to define the hydraulic performance of a pump. Pump hydraulic performance ranges from Radial-Vane flow to Axial Flow.

Think of Radial-vane area as low flow high head and axial flow as high flow low head. Depending on different applications, different hydraulics will need to be selected. In our experience, oil & gas is usually associated with low flow, high head. On the other hand, applications that involve water such as power or municipal usually see high flow low head. If you want to go deeper into the theory between head and flow, look into the Bernoulli equation.

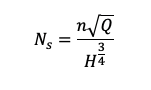

Specific speed is calculated by:

Where n = RPMs, Q = flow rate, and H = head. Note that it is important to be consistent in your units when you are performing calculations. If the output you want is in imperial units, then your inputs must be in imperial units. In this case, Q is in GPM and H is in ft.

Although specific speed is not directly tied to interpreting a pump curve, it is important to understand how to characterize different pump performances.

Pump Efficiency

Efficiency describes what we get over what we pay. In the case of pumps, what we get is the water power output. What we pay to get this water power output is the shaft power input, that is provided by the motor.

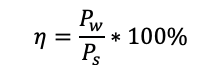

Overall efficiency can be calculated by:

Where Pw and Ps represent water power output and shaft power input, respectively.

Horsepower

Water Power Output

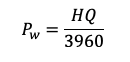

A simple calculation, in imperial units yields the following for water power output:

Where H represents the head and Q represents the flow rate. Knowing this, for any head and flow rate, we are able to calculate what the water power output is along the curve.

Shaft Power Input

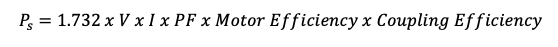

The shaft power input is the power that is provided by the electric motor running the pump. The shaft power input is expressed by the following formula:

Where V represents voltage in volts, I represents current in amps, and PF is the power factor of the motor. The motor efficiency and coupling efficiency are variables that are provided the the respective suppliers.

Ps is representative of brake horsepower in imperial units.

Pump curve generation software will do all of these calculations so that you won’t have to. It is important to understand what gets fed into the pump curve generation software, so that we better understand the outputs. Many of the parameters in the pump curve are dependent on flow and head, therefore if we have our inputs, that means we have our outputs.

BEP

BEP stands for Best Efficiency Point. It is important that you are maximizing the efficiency of your pump upon operation. Otherwise, you will be adding onto the system’s overall kW/hr (more importantly $$$). Often times its difficult to think about the money when all we are focused on is performance. It is very easy to forget about the cost when all we are focused on is meeting our operating conditions.

The above are all of the parameters you need to understand so that you can pick the right pump for your application. Take into account all of these parameters and you will avoid tunnel vision and you will select the best suitable hydraulic for your needs.

POR

The preferred operating range (POR) is the region of the pump curve that is defined relative to the BEP point. The POR, defined by various hydraulics standards such as HI or API 610 varies. However, the POR usually lands at about 70% to 120% of flow at BEP. In an ideal case, you will always be running your pump in your preferred operating range. Running at BEP all the time would be the best case scenario in terms of efficiency, but

AOR

Allowable Operating Range, which is the segment of a pump curve determined by the pump manufacturer that defines where the pump can be operated without significantly altering the performance life of the pump. The AOR is determined by the respective pump manufacturer, through trial and error – and is what the manufacturer deems acceptable per the hydraulic.

See the curve below for a summary of where the points such as BEP, POR, and AOR align.

The above represents a visual of all of the parameters superimposed into one curve. This gives you an idea of all of the different parameters such as where BEP lines and a visual of NPSHa and NPSHr. Understand what each of these parameters refer to and you will have all you need on how to select a pump from curve.

How To Select A Pump From Curve – Example

Now that we have covered what the individual parameters mean on how to select a pump from curve, we are ready to perform a sample exercise.

Based on the sample pump curve above, let’s say we want a pump that produces 75 ft of head at a flow rate of 100 GPM. We look at 75 ft of head on the y-axis and draw a straight line to the right up until it intersects with 100 GPM. Looking at the intersection between the purple lines (our inputs), it falls JUST below the head-capacity curve for the 5.00 IN DIA impeller. For our example, we can conclude that the 5.00 IN DIA impeller is suitable for our hydraulic. If we look very closely, we see that the intersection lies just above the 3HP line, meaning that we would have to size all the way up to a 5 HP to meet our hydraulic performance.

About the author

Kazuyoshi Fujimoto, PE

Founder | Engineering Career Coach | Principal Mechanical Engineer

Kazu oversees all of ultmeche’s engineering services. He provides consulting such as resume reviews, rewrites, mock interviews, and all services career related. Additionally, Kazu performs consulting work regarding Oil & Gas, Automotive, and Aerospace & Defense. Kazu is licensed as a professional engineer in the state of California and has 9+ years of experience in Oil & Gas, Automotive, and Aerospace & Defense.