The future of mechanical engineering is headed towards merging with tech. Hands down. Mechanical engineering skills will become integrated with coding, AI, and machine learning. There is no other way we can see the future. The world is shifting at a very fast pace. COVID-19 has accelerated remote working and leveraged the use of technology to maintain current business operations.

Today, mechanical engineers are responsible for tasks such as designing, generating bills of materials, analysis, and testing of mechanical systems such as cars, planes, and various machinery. If you’re an engineer in the industry, you should notice that companies are shifting towards a digital transformation.

February 29, 2024

The Present State of Mechanical Engineering

We still see big name companies reference old drawings created by 2D drafting (with coffee stains!). Companies will even have libraries of all of these “old” drawings – in torn apart binders that you can barely even read! As companies start transferring a lot of their engineering data into the cloud, the next step is to automate engineering. Although this may be a slow process, this will occur within the next 10-30 years. Compare it to when computers came out and CAD as a skill became utilized. Just like how 2D drafting becomes obsolete, the current day to day tasks of mechanical engineers will become obsolete if you don’t learn tech. One thing we can learn from this about humans is that humans are not adept to change.

From a company profitability perspective, you have to see this move towards code coming. Companies will do whatever it takes to reduce their overhead expenses. Engineering salaries are expensive, why pay engineers, when companies can pay an upfront cost to reduce fees throughout their lifetime.

You will hear “digital transformation” over and over again in company meetings and presentations. Executives will rave about this in their earnings reports to their shareholders. Investors will be happy to read about digital transformations because this will lead to higher operating income.

Future of Mechanical Engineering Product Focus

Robotics

Robots don’t get tired, they don’t complain, and there are no HR issues with robots. Once robots are set and running, they will replace blue-collar tasks. Tasks like changing out bolts, operating cranes, drilling holes, CNC machining all have the capability to be replaced by a robot. Robots can even perform QA inspection, through leveraging AI and machine learning. The challenge will be to program robots to do these tasks, as humans already have a challenge doing blue collared work as is.

EV

Major luxury car manufacturers (Tesla, Audi, Mercedes) have already gone this direction! With political influence such as Biden planning to cut fossil fuel emission 50% by 2030, we will start seeing more EVs on the road. If you live in Los Angeles, California – you will already see a bunch of Teslas on the road. Luxury EVs are also a status symbol. There is a huge market for these vehicles as they display wealth and status.

With States making moves to ban combustion vehicles, EV is the clear winner for the future. If you’re shopping for a car, look into EVs instead of combustion engine vehicles. If you want to save money, there are federal or state incentives that are provided when you purchase an EV.

Wind

Reducing fossil fuels, means more renewable energy sources such as wind turbines! What’s so special about wind turbines are the manufacturing methods to make them! To stay competitive in the marketplace, companies will need to be more efficient in manufacturing wind turbines.

According to US Geological Survey, wind turbines are made of 71-79% steel, 11-16% composite materials such as fiberglass, resin, or plastic, 5-17% cast iron, 1% copper, and 0-2% aluminum.

Research and development efforts are currently making composite manufacturing more efficient. As a result, wind turbines made from composite materials will become prevalent in the next 10 years.

Solar

Building take up a lot of energy and resources, so as a result, we see buildings and homes start widely integrating solar panels for energy. An upfront cost of a few thousand or a few hundred thousand dollars to save millions is a no brainer. More efficient means of manufacturing solar panels will be developed in the future, and we will see more widespread use. Political influence will also make solar panels more widespread.

Future of Mechanical Engineering Skillsets

Product Lifecycle Management

For companies to be efficient, they will need to leverage the use of product lifecycle management software such as Siemens Teamcenter and integrated with enterprise, resource, planning software such as SAP. Software will need to be able to “talk to each other”. If everything can talk to each other, then it will be easy to track items, meet delivery dates, and reduce non conformances.

3D CAD Modeling with Coding

Parametric modeling already exists to some degree, but its use will be more prevalent in the industry. Universities should start teaching this skill, as it will make students more equipped to contribute value when they are employed as an engineer. Given a model, we set dimensional values as parameters. The parameters can be used as a number, and changes to the number will make changes to the dimension, essentially changing the model. If we combine code with parametric modeling capabilities, there will be no need for an engineer to start modeling systems, as it will be replaced by code.

Imagine modeling living rooms in CAD just with lines of code. This could be essential for real estate businesses to adopt this type of imagery, because the listings need to look their best!

3D Modeling Through AI

This will utilize a method similar to 3D Cad Modeling with coding. Through AI, complex systems could be modeled the best way possible, in the least amount of time. This will save hundreds, if not thousands of hours as opposed to if an engineer were to design using CAD. Those hours will translate into dollars saved. 3D modeling through artificial intelligence will be a heavy investment in the future.

Imagine a robot doing your computer work for you. Intense.

Quality Inspection Software Using Machine Learning

Machine Learning utilizes coding and algorithms that improve upon experience and given data. For example, if there was an application where a company needed to inspect a certain defect on a part, machine learning can be utilized to quickly scan for said defect. This beats having to have a human look for said defect. Humans have error associated with themselves, but inspecting using ML will not.

Future of Mechanical Engineering Job Outlook

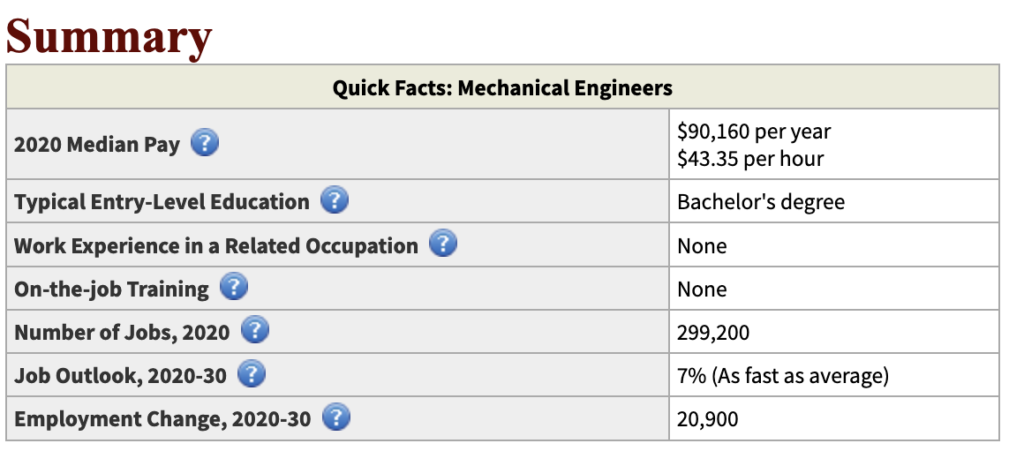

According to the US Bureau of Labor Statistics, job outlook is expected to grow 7%, as fast as average. As fast as average means that other industries will adopt the same changes, so tech is going to boom no matter what sector. We cannot think of any industry that will not be influenced by tech. Mechanical Engineering, on the other hand, will not be a game changer by itself.

We want to emphasize the importance of learning the skillsets described above. Start learning how to be creative, as many of the day to day tasks that are done today can be automated. Make sure that you develop a skillset that is not replaceable by code, and you will have no problem finding a job as a mechanical engineer.

Search some of this stuff on YouTube. Read books about these subjects. Start learning more about these things everyday, as the knowledge will compound.

Want to work in Thermodynamics? Apply the skills mentioned in this post and become dangerous.

Unfortunately, you cannot become successful just by going to school. There are skills outside of school that you need to learn such as any coding tech related. The good news is that you are way ahead of your peers if you realize this. We are looking at a 10-30 year horizon for these changes to start surfacing, so start learning these skills now. You should’ve started yesterday, but the second best time is now.

About the author

Kazuyoshi Fujimoto, PE

Founder | Engineering Career Coach | Principal Mechanical Engineer

Kazu oversees all of ultmeche’s engineering services. He provides consulting such as resume reviews, rewrites, mock interviews, and all services career related. Additionally, Kazu performs consulting work regarding Oil & Gas, Automotive, and Aerospace & Defense. Kazu is licensed as a professional engineer in the state of California and has 9+ years of experience in Oil & Gas, Automotive, and Aerospace & Defense.

4 thoughts on “The Future of Mechanical Engineering”