Don’t understand basic machine design interview questions for mechanical engineering positions?

You won’t get the job.

Knowing basic machine design is necessary both for a job interview and trivial engineering knowledge.

You won’t be providing any value at all if you don’t understand the basics of machine design.

The best engineers all have an in depth understanding of machine design and are able to utilize machine design principles quickly on their feet.

December 21, 2024 by Kazu Fujimoto

The following are basic concepts that you should know regarding machine design interview questions.

Make sure you know these questions both so that you are ready for an interview and if you also want to be a good mechanical designer.

Book a technical mock interview with Kazu to 10X chances of landing the engineering job.

What is beam deflection?

Beam deflection is the distance a beam moves upon being subject to an external force. Deflection analysis is important such that we need components such as snap rings, gears, transmissions, shafts to ensure optimal mechanical performance. Improper design due to not taking into consideration beam deflection will cause problems such as teeth not meshing on gears or excessive vibration on shafting.

What is a rigid structure?

A structure is rigid when it does not bend, deflect, or twist too much upon an external force, moment, or torque is applied on it.

What is a flexible structure?

A flexible structure is when the movement of a structure is very large upon being subject to an external force, moment, or torque.

What is elasticity?

Elasticity is the property of a material that represents its ability to return to it’s original shape after having been deformed.

What is a spring?

A spring is a mechanical design element which exerts a force after it is deformed.

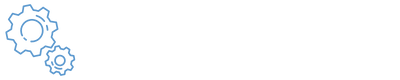

Explain the behavior of the beam deflections while supported in the following conditions – simply supported, on two cylinders, or dish shaped round disk fixed at both ends

(a) – Linear Spring

A simply supported beam with a load applied shows a linear deflection related to the force (as long as the elastic limit is not exceeded).

(b) – Stiffening Spring

A beam supported on two cylinders makes it so that the beam that is supported has a lower length. Because a lower length beam requires a larger force, this beam essentially becomes stiffer.

(c) – Softening Spring

The force to flatten the disk increases at first, but then decreases as the shape of the disk becomes “flat”. If you see a mechanical element with this type of characteristic, refer to it as a nonlinear softening spring.

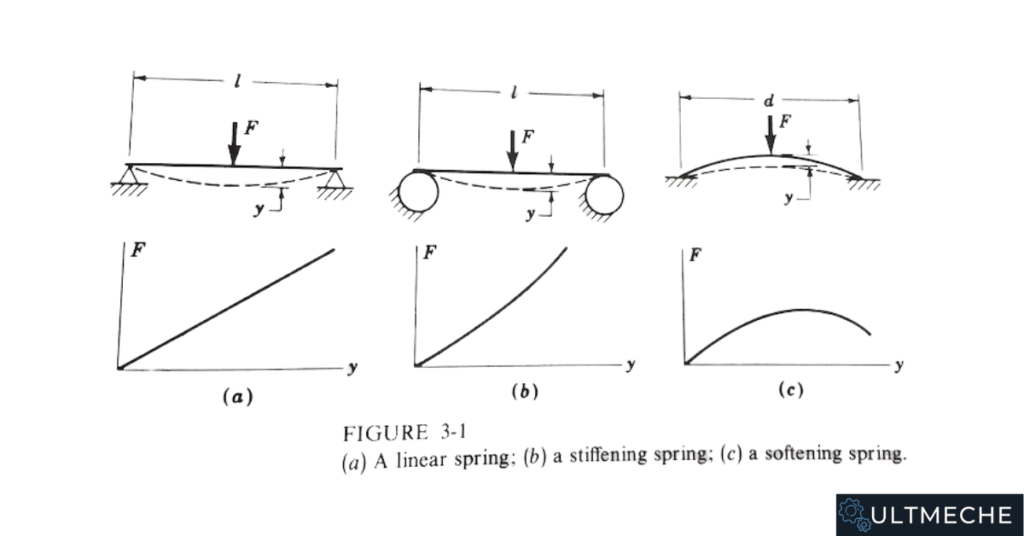

Determine how to draw a shear force and bending moment diagram given a beam length of X applied with a uniform load.

See this example.

The reaction force for this example would be R1 = R2 = 800 lb.

Shear forces would be V0 = +800 and V1 = -800 lb

The bending moments are zero at the end because the beam is simply supported.

Notice beam deflection curve has negative slope at left boundary and positive at right boundary.

Slope is zero at the center of the beam.

Think of this example as first derivative and second derivative.

What is the method of superposition?

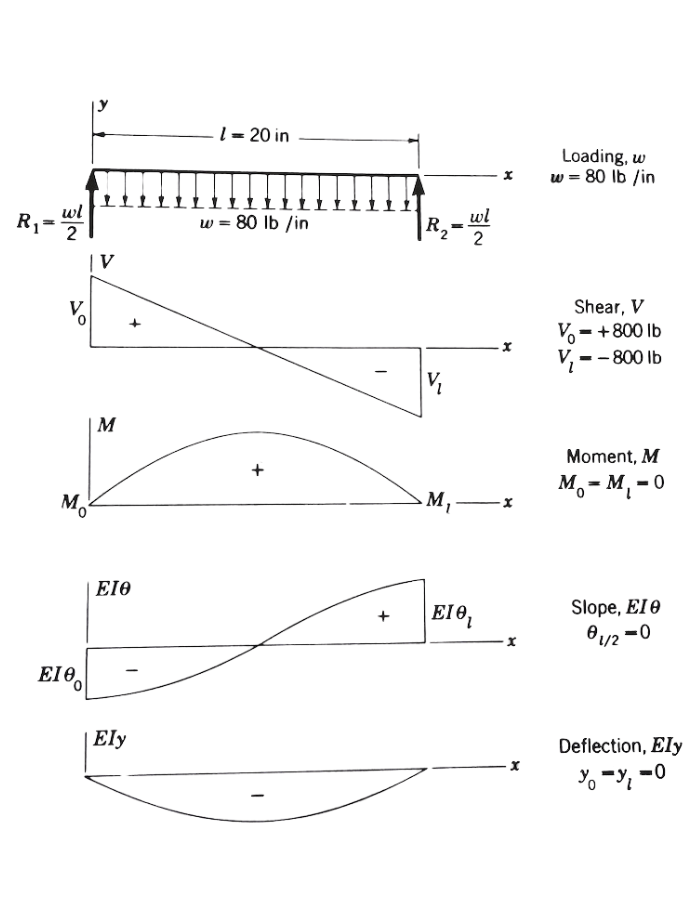

The method of superposition applies to that of beam deflection in which for linear force deflection problems, the relationship between force and deflection are linear. The method of superposition relies on the principle that deflection at any point in a beam is equal to the sum of deflections caused by each load acting separately.

This is a great use case to simplify beam deflection calculations.

Note that in the industry, engineering stress calculations will rely on beam deflection principles.

Apply these general beam deflection equations to your application as best as possible. Engineering is full of making assumptions and using engineering knowledge and reasoning to justify.

What are some critical design factors to take into consideration regarding machine design?

Critical factors to take into design consideration are:

- Operating conditions

- Design for Assembly

- Design for Manufacturability

- Cost competitiveness

- Engineering principles depending on product application

How do we ensure that a design is practical and economical?

Utilize the following principles to ensure that a design is practical and economical

- Use standard sizing

- Source lowest cost material while ensuring to uphold quality

- Simple geometry

- Simple machining methods

- Determine reasonable factors of safety

- Use engineering judgement to determine best case operating conditions

Explain the various forms of mechanical stresses

What is the definition of Stress?

Stress is defined as the physical value of force divided by the area subject to the force.

Stress = Force/Area, denoted in units such as psi or Pascals

Check out for a more detail: What is Stress in Engineering?

What is yield strength?

Yield strength is the point where a material will stop linearly deforming, and start non-linear deformation.

What is ultimate tensile strength?

Ultimate tensile strength is the highest stress a material can withstand before failure.

What are allowable stresses?

Allowable stresses define the limits of the stress the materials can be subject too. If the stress exceeds the allowable, the part will not meet its failure criteria and be at risk for failure.

What is shear stress?

The shear stress of an object is a stress subject to an object’s shear plane.

How is fatigue strength and endurance limit of an object determined?

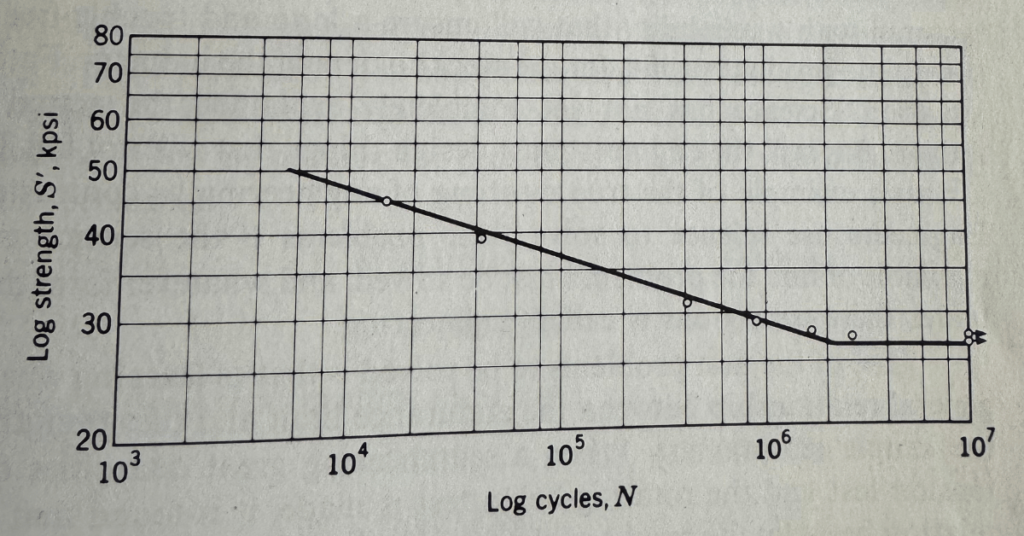

To determine what the fatigue strength of materials are, material specimens need to be subjected to repeated or varying forces of magnitudes while cycles are counted to destruction.

A large number of tests at different operating speeds and conditions will be conducted and plot something called an S-N diagram.

The strength “corresponding to the knee of the curve” is known as the endurance limit – essentially the value in which a part can theoretically be subject to infinite life.

Airplanes and automobiles represent some practical applications in which fatigue strength and endurance need to be determined.

What is temperature factor?

Temperature factor is represented as Kd in applications and is taken from actual tests. Refer to specs and sources such as MMPDS for temperature knockdown factors (TKF) which you can apply to your loading conditions when you determine what load values you will need for qualification and static testing.

Closing Thoughts on Machine Design Interview Questions

Machine design is a very fundamental engineering class that will stay throughout your entire career as a mechanical engineer.

There’s so much to cover from beam deflection, to fatigue analysis, to economical automotive and aerospace design.

Use these basic machine design interview questions as a guideline to prepare yourself.

Want to learn how to write a good mechanical engineer resume and more about material engineering (a really good industry to go into if you want to utilize strength of material principles in your career)?

Check out: Entry Level Mechanical Engineering Resume and What is Material Engineering

Don’t forget to check out our career services as we provide resumes, cover letters, interviews, and LinkedIn optimization for those specializing in engineering careers.

Book a technical mock interview with Kazu to 10X chances of landing the engineering job.

Our mock interviews break up behavioral and technical step by step and as a result will prepare you for challenging interviews.

About the author

Kazuyoshi Fujimoto, PE

Founder | Engineering Career Coach | Principal Mechanical Engineer

Kazu oversees all of ultmeche’s engineering services. He provides consulting such as resume reviews, rewrites, mock interviews, and all services career related. Additionally, Kazu performs consulting work regarding Oil & Gas, Automotive, and Aerospace & Defense. Kazu is licensed as a professional engineer in the state of California and has 9+ years of experience in Oil & Gas, Automotive, and Aerospace & Defense.