If you’re an engineer you absolutely need to know what is stress in engineering. Stress is a fundamental phenomenon that many mechanical, electrical, and civil systems are subject to.

As an engineer you will be designing systems, and these systems will undergo stress. It is your job as an engineer to make sure that the parts and systems you design can handle these stresses.

What is the formula for stress?

The formula for stress is represented by a force over a unit area.

Physically speaking, the stress is the reaction that you see based on the force upon that certain area.

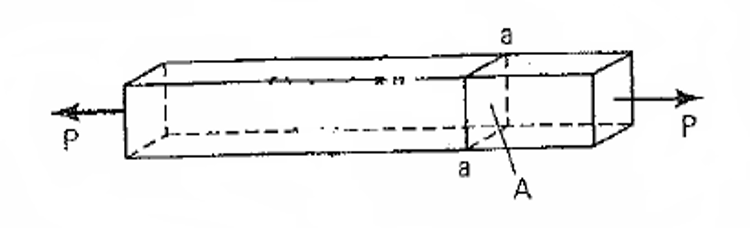

The most basic form of stress to understand is uniaxial stress.

An example of this would be a force P acting upon a bar with cross sectional area A.

To calculate stress, we use the formula:

Different forms of Stress in Engineering

In engineering there are many different forms of stress for different applications.

Different forms of engineering stress consist of those such as:

- Normal Stress

- Shear Stress

- Planar Stress

- Principal Stresses

- Compressive Stresses

- Tensile Stress

We’ll break down what some of the basic forms of these stresses are so that you can understand.

What is normal stress?

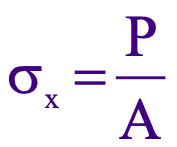

Normal stress consists of stress acting upon the “normal” axis upon a component.

If we take an inclined plane in the beam shown above, the normal stress would be represented by the x’ axis.

Check out: Normal Stress Formula

Compressive Stresses and Tensile Stresses

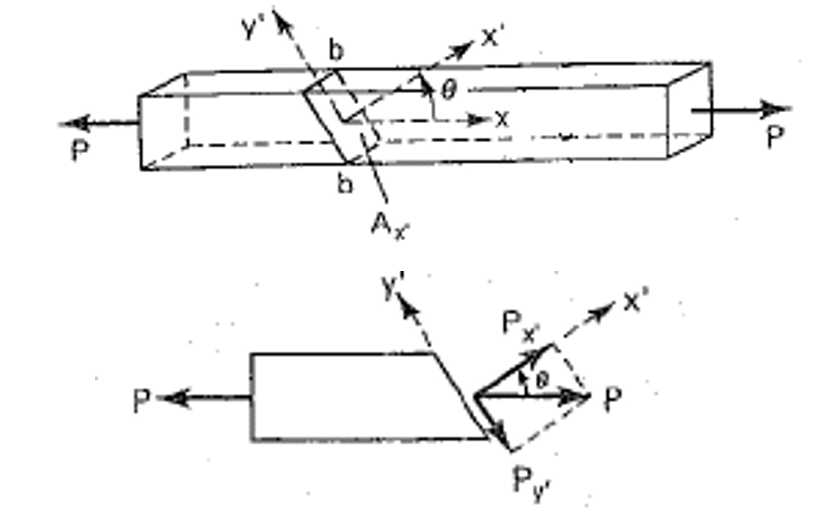

Along the normal axis of a body such as a beam, depending on the force, we see compressive or tensile stresses.

Compressive Stresses

Compressive stresses are what happens when an object undergoes a force such as crushing or squeezing.

Tensile Stresses

Tensile stresses are what occur when an object undergoes a force such as pulling or stretching.

Beam Bending

Beams are a very important component in engineering, as a result, it is important to analyze them.

When a beam is bent by loading, a bending Moment M will occur as a result of that initial loading.

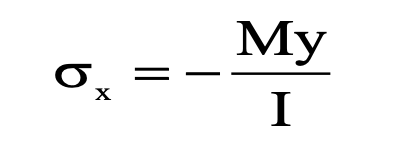

To calculate the normal stress associated with the bending moment on the beam we use:

What is shear stress?

The shear stress of an object is represented by the stresses on an object’s shear plane:

Shear Stresses in Beams

A common application we look at in engineering regarding shear stresses are beams.

When beams are bent by transverse loads, we usually see a bending moment M as we have discussed above, and a shear force V acting upon that respective cross section.

Engineering systems are subject to multiple types of stresses, so as a result we need to take various forms of them in our calculations.

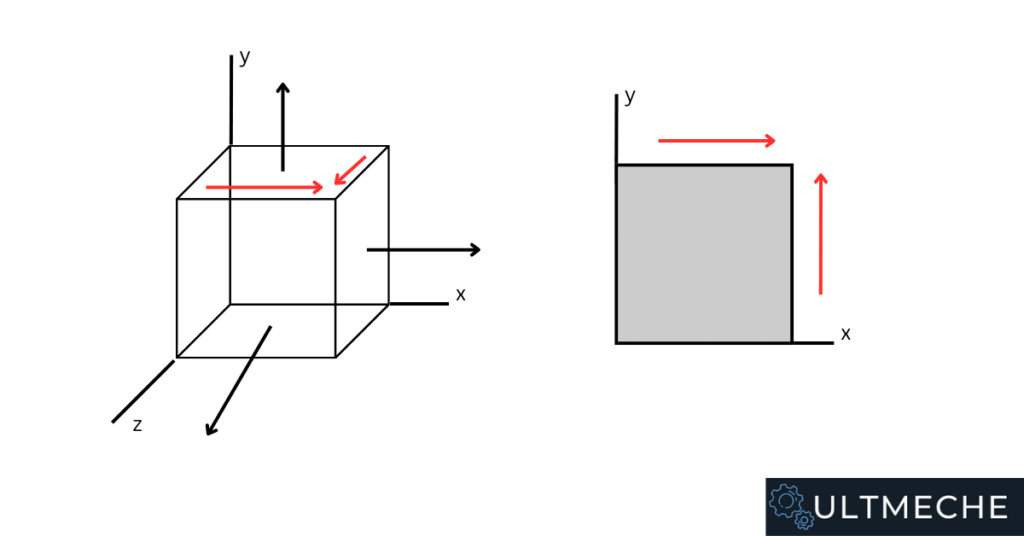

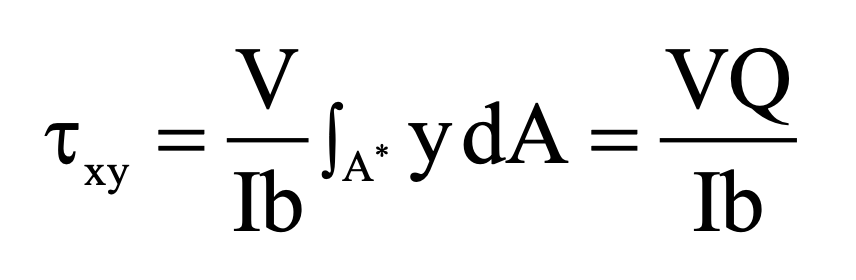

Shear stress for a beam can be written as:

What is planar stress?

Planar stresses represent stresses acting upon any plane of an object such as a beam, sphere, or shaft.

To simplify some of our engineering analysis, in the industry, we will take a cross section and perform an analysis on that specific cross section only. This is because it’s a much simpler means of analysis. Taking an analysis of the entire beam vs. a specific cross section will be lengthy and require the use of analysis software.

It is important to remember that when you are designing or analyzing as an engineer, that you are using the most economical tools and solutions.

(Engineers work for companies and the main goal of these companies are to make profits and boost shareholder revenue)

Refer back to the normal stresses section of this page for a visual on planar stresses.

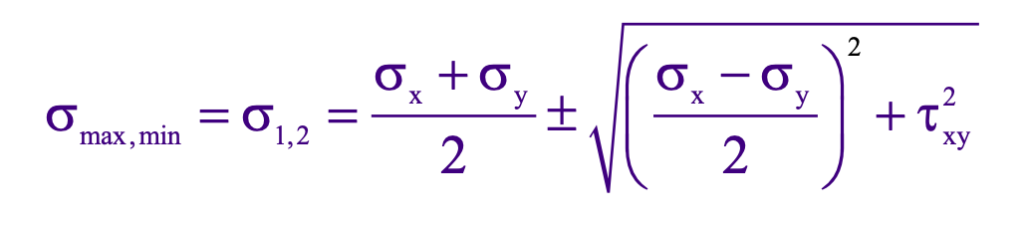

What are principal stresses?

Principal stresses represent the maximum or minimum stresses subject to a body.

When we are designing engineering systems and determining geometry such as lengths and thicknesses, we need to take into account maximum stresses.

This is why we care so much about principal stresses.

A simple way to calculate principal stresses is using the equation:

Engineering Stress Examples

In a strength of materials class in engineering or in the industry, you will be required to calculate some forms of stress.

Below are some simple example problems of stress that you should know and refer back to when presented a similar problem in the industry.

Beam Deflection Example Problem

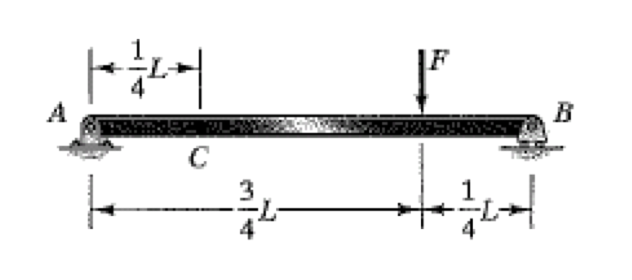

For the beam in the figure below, determine the internal forces and moment at point C.

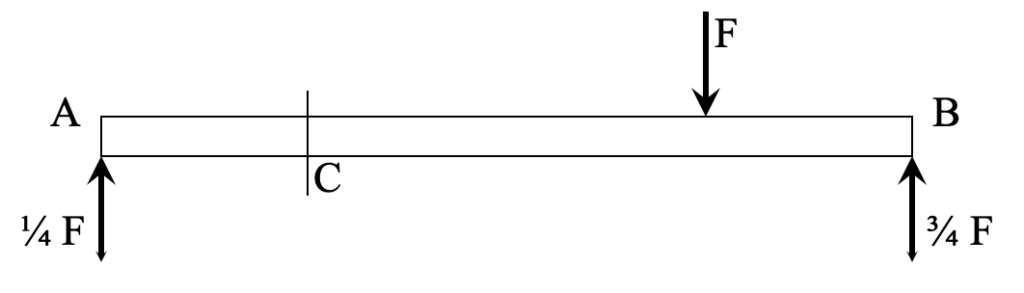

Step 1 – Draw free body diagrams of the entire beam and solve for the support reactions.

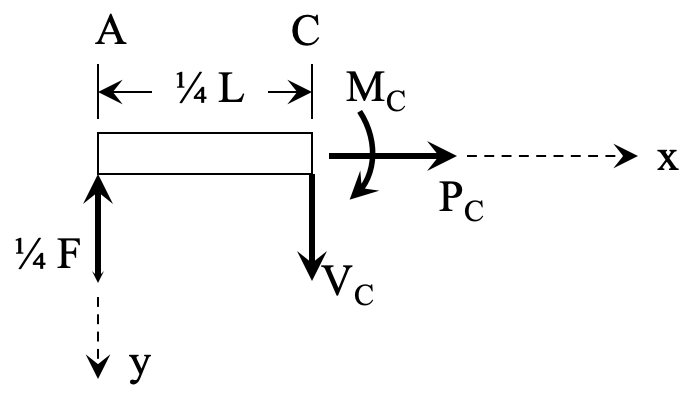

Step 2 – Imagine a cut through the cross section at C and draw the free-body diagram of the left part, AC, including the internal forces and moments FC, VC, and MC in their defined positive directions.

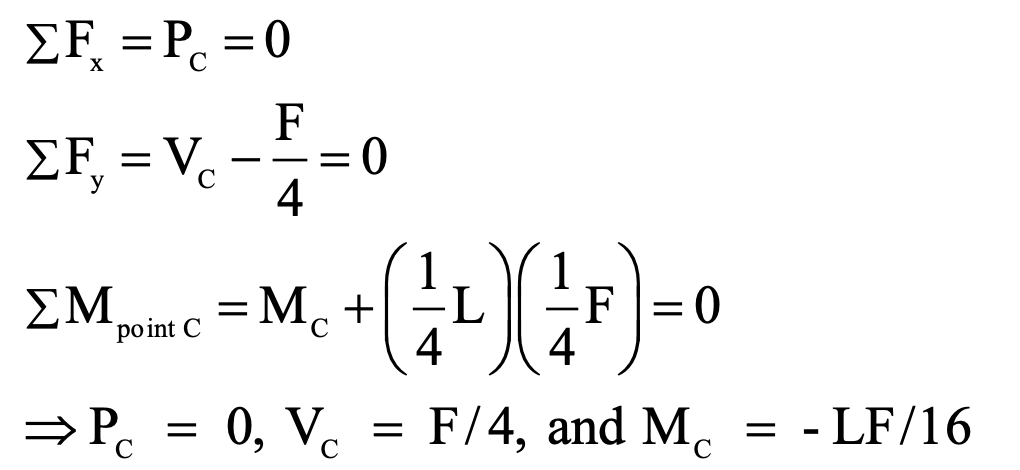

Write down equilibrium equations for the free body and solve for Pc, Vc and Mc

Commentary

It’s really important to having mechanical aptitude when solving for these problems. You will also need basic arithmetic skills and deductive reasoning such as drawing free body diagrams and finding unknown forces.

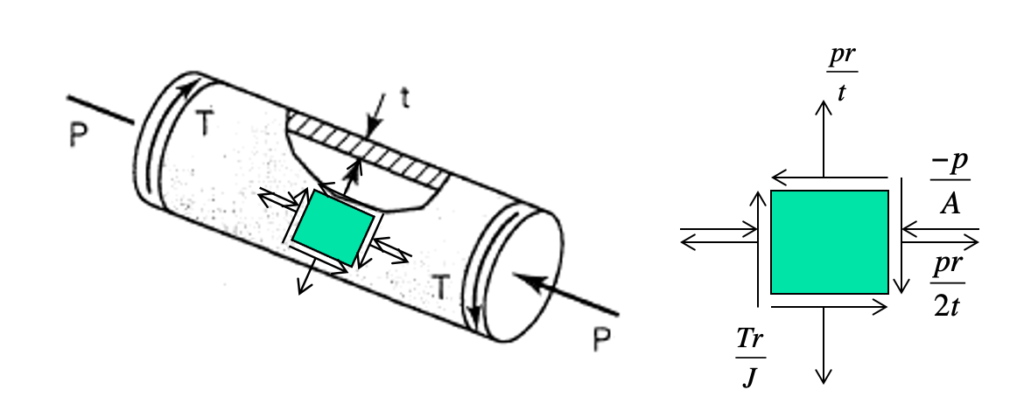

Pressure Vessel Example Problem

A thin-walled cylindrical pressure vessel of radius 120 mm and a wall thickness of 5 mm is subjected to an internal pressure of p = 4 MPa.

In addition, an axial compression load of P = 30π kN and a Torque of T = 10πkN.m are applied to the vessel through the rigid end plates:

Determine the maximum shearing stresses and associated normal stresses in the cylindrical wall. Show the results on a properly oriented element.

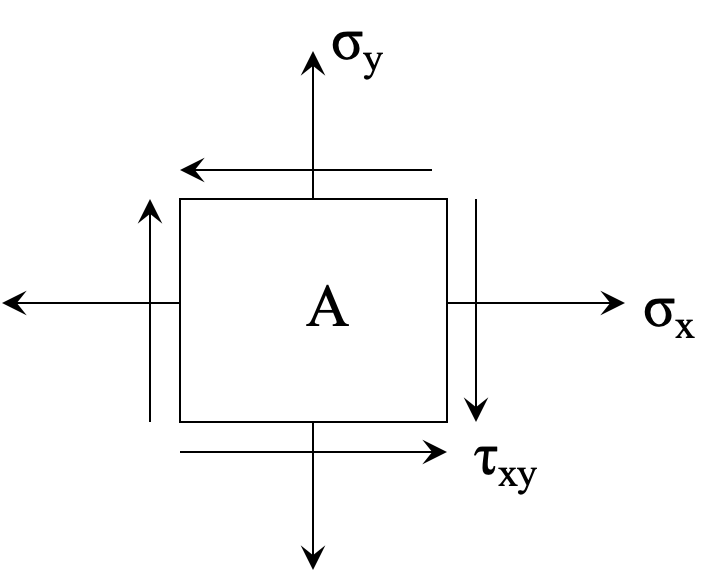

Let’s take into account an element on the surface of the cylinder and indicate all the stresses applied on the element:

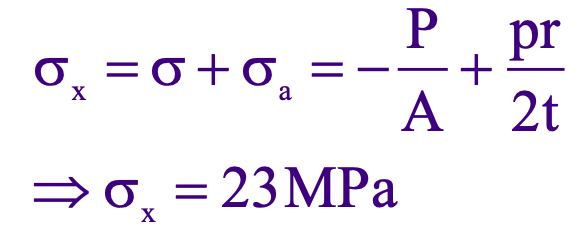

Normal Stress in X direction

The normal stress in the x direction is due to compressive loading and internal pressure (axial stress in cylinder wall):

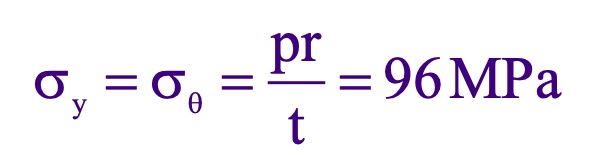

Normal Stress in Y direction

The normal Stress in the y direction is due to internal pressure (tangential stress in cylinder wall):

Maximum shearing stress

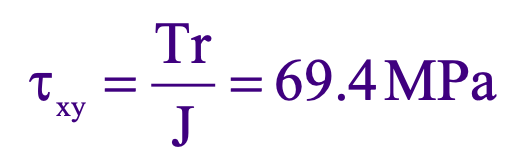

The maximum shear stress on the pressure vessel is due to torsion

Commentary

The pressure vessel example problem is actually really easy. It’s a simple “plug and chug” type of engineering problem.

Although the math is very simple, the hard part is conceptually understanding what stresses are going on in the pressure vessel.

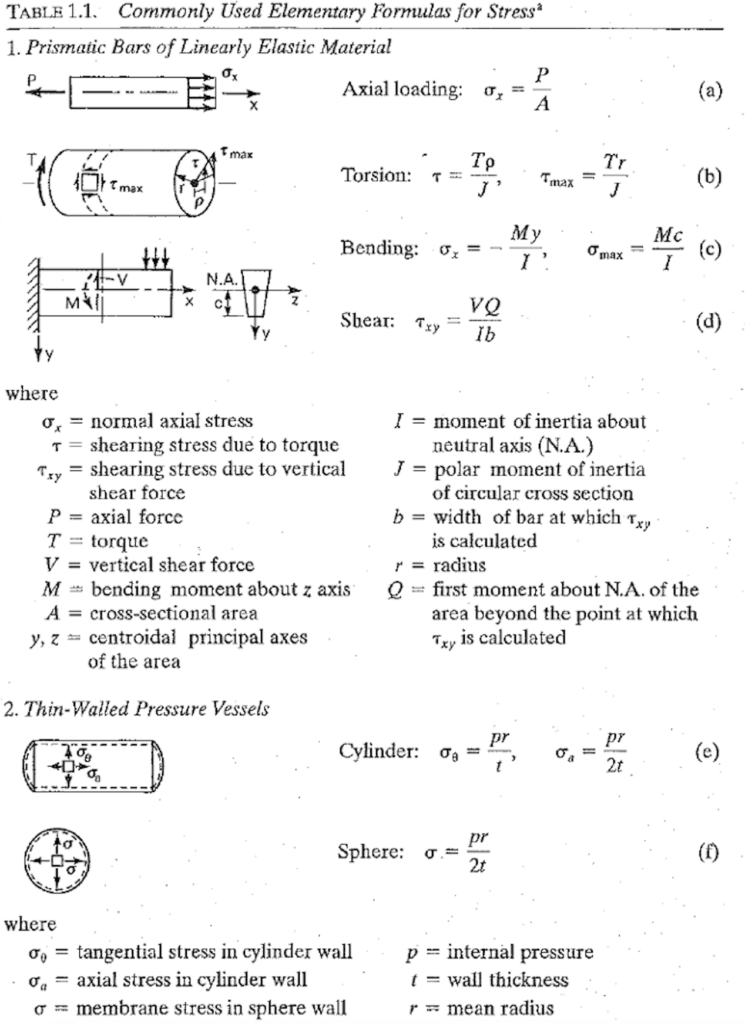

Commonly used formulas for Stress in Engineering

Refer to the table below for some really common formulas used for stress in engineering.

Closing Thoughts on Stress in Engineering

Stress in Engineering can get very complicated, but when you break down the concepts, it gets simple to understand.

The hard part is tying these simple concepts with providing practical and economic solutions to the customer in engineering companies.

Want more resources of strength of materials?

Check out: Strength of Materials Interview Questions – Top 23 and Mechanical Engineering Mock Interview

About the author

Kazuyoshi Fujimoto, PE

Founder | Engineering Career Coach | Principal Mechanical Engineer

Kazu oversees all of ultmeche’s engineering services. He provides consulting such as resume reviews, rewrites, mock interviews, and all services career related. Additionally, Kazu performs consulting work regarding Oil & Gas, Automotive, and Aerospace & Defense. Kazu is licensed as a professional engineer in the state of California and has 9+ years of experience in Oil & Gas, Automotive, and Aerospace & Defense.

7 thoughts on “What is Stress in Engineering?”