General Knowledge Statics and Strength of Materials You Should Know

February 29, 2024Statics and strength of materials is huge to understand. Although they are very difficult concepts at times and it may seem impossible to wrap your head around everything, at least understand the basics. Both in an academic and an industry setting.

If you’re an engineer in the industry:

You should be able to look at a design and understand what is going on. For example, if you see a shaft, you should start drawing free body diagrams in your head and understand the stresses of the shaft. A shaft is used in a motor and we know that a motor rotates. So the shaft is subject to torque. Also, there is some type of load the shaft needs to rotate, so the shaft needs to overcome its moment of inertia. Let’s say we’re talking about a horizontal shaft – then there are going to be constraints. Understand the application of fixed, hinged, pinned constraints.

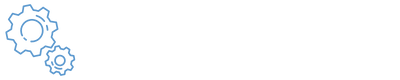

Remember these types of problems? Although you don’t need to solve problems like these, you will need to understand load distribution on beams and how beams will react. Where is the maximum bending stress? Where is the highest bending moment? This will not apply only to beams, but for systems like pumps, turbines, compressors, cranes, equipment, the list goes on.

If you’re an engineering student:

Pay attention to the basics of each concept when you’re taking strength of materials. Don’t focus on memorizing the equations that you’re given, but understand what the parameters are. Understand stress, strain, torsion, bending moments, inertia, failure, and fatigue. Don’t skip these sections! Pressed for time and you don’t have the bandwidth to make sure you understand? Too bad. You need to understand this stuff as a mechanical engineer.

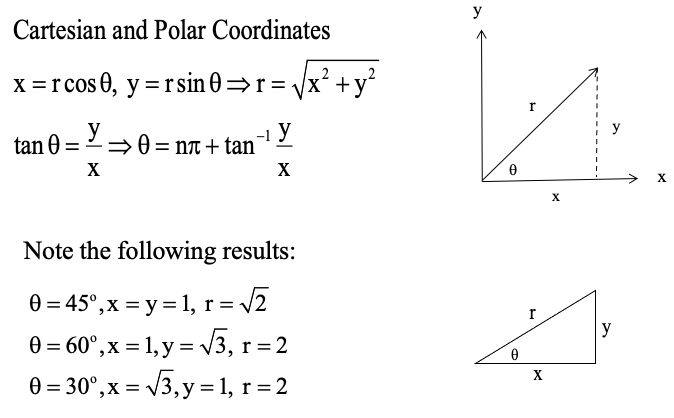

Make sure you understand all of the math classes you’ve taken at this point – geometry, trigonometry, and calculus. These classes are going to follow you around until the end of your life as an engineer.

Hint! This type of math should be second nature to you:

What you need to know about statics and strength of materials after class

Think strength of materials ends in the classroom? Wrong! This class is very applicable to your engineering career, its not even funny.

As an engineer, you need to understand the what the following are:

- Stress

- Strain

- Torque

- Moments

- Fatigue

- Free Body Diagrams

- Stress Concentration

- Load Distribution

- FEA

So if had a hard time in your strength of materials class, you are in for a rude awakening. Often times you will need to be able to think quick on your feet, review a design and understand what is going on, and provide value to your colleagues.

If you’re not able to do so, you’re not going to be respected. You won’t be put in for promotions. Your responsibilities will fall.

Make sure you understand strength of materials.

Application of Statics and Strength of Materials

Pumps

Can you look at the picture above and “feel” what is going on?

Well, we see fluid being moved from inlet to outlet. The flow could be both ways, we don’t have enough information to determine the direction of flow. But, if we understand that the piping system is filled with fluid, we can immediately think that the system is subject to hydrostatic forces. In strength of material terms, we’d start looking at hoop stress and radial stress. The material selection of the piping needs to be strong enough to handle that of the stresses generated from the hydrostatic pressure.

Turbines

Renewable energy is going to be a booming industry as we expect political influence towards renewable energy. With renewable energy comes systems like hydrostatic dams or wind turbines. Imagine a wind turbine rotating. A wind turbine needs to overcome its moment of inertia. Because the wind turbine is rotating, the blades of the turbine will be subject to shear stress. Make sure you can picture this.

Another hint towards the future – composite manufacturing methods are being looked into for the most optimal means of manufacturing wind turbines. Look up resin transfer molding.

Planes

Yup, planes. The big “F” word – Fatigue. Planes undergo long lifetimes and are rated to fly a very high number of cycles. When a plane is subject to alternating stresses – think in take off, flight, and landing – fatigue is a big consideration in airplanes. If fatigue is not accounted for, the plane will crash and lives will be lost.

Strength of materials is a very serious matter and as a student or engineer you need to have a valid understanding of strength of materials.

About the author

Kazuyoshi Fujimoto, PE

Founder | Engineering Career Coach | Principal Mechanical Engineer

Kazu oversees all of ultmeche’s engineering services. He provides consulting such as resume reviews, rewrites, mock interviews, and all services career related. Additionally, Kazu performs consulting work regarding Oil & Gas, Automotive, and Aerospace & Defense. Kazu is licensed as a professional engineer in the state of California and has 9+ years of experience in Oil & Gas, Automotive, and Aerospace & Defense.