Strain in engineering is really important to understand, so you really need to know what it is as an engineer. This is information that customers want for the design of structures and mechanisms upon loading.

Strain is a dimensionless parameter that describes elongation over the total length of an object.

What strain tells us is how much an object elongated relative to how long it is. This gives us a much more extensive measurement than displacement.

Why do we care about Strain in Engineering

In Engineering disciplines such as mechanical or civil, we will deal with physical systems that are subject to forces. Forces such as weight, load, compression, tension are acted upon systems which will cause the systems to experience strain.

Studying the strain of a particular object or material will tell us as engineers that this product or system will be safe under the loads they are subjected to.

This is data that we give to the customer and in return, engineering companies get paid.

Engineers will submit deliverables such as documents, reports, charts, graphs, and stress-strain data to the customer. The customer can be anyone ranging from internal employees, project management, or outside customers.

Strain Formula

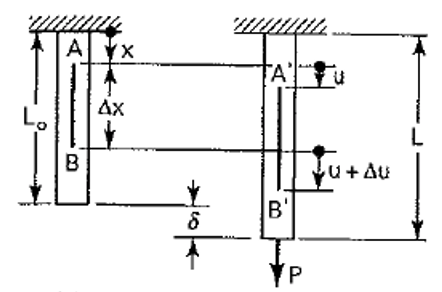

Let’s take into account an axially loaded beam shown in the figure.

Element AB = ∆x undergoes deformation to become the element A’B’:

A has been displaced by an amount u, and B by u + ∆u (u is the universal designator for displacement in engineering).

The length of the line element A’B’ is ∆x + ∆u, in which we will use in the next portion of the equation.

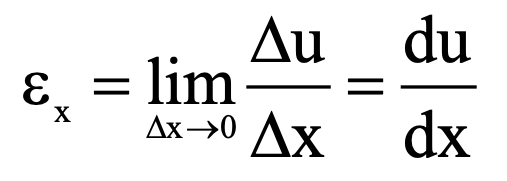

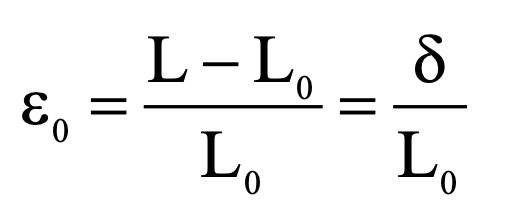

The strain in the beam at the point A is defined as the change in length per unit length as ∆x → 0 and is given by the equation:

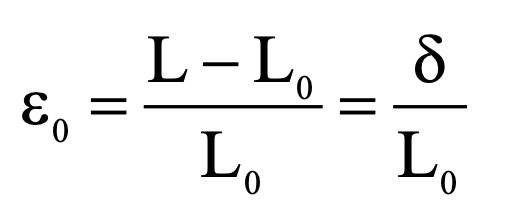

If the deformation is distributed uniformly over the original length, the normal strain may be expressed in the form such as:

Simply put, the equation represents the change in length of an object over the entire length.

Check out: Strain Formula

Strain Gauges

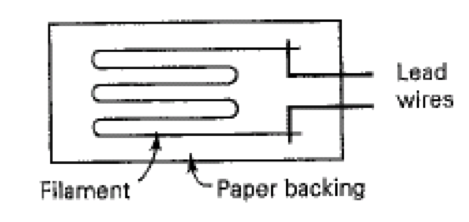

Strain gauges are the physical components that are put on parts or materials that we get measurements of strain from. It is common in the industry to bond strain gauges to parts using methods such as adhesives.

Bonded electric wire or foil resistance strain gages are often used to measure the average strain. Either at a point on the free surface or in the interior of a solid. The strain gage consists of a grid of fine wire filament cemented between two sheets of treated paper or plastic backing:

The operation of the bonded strain gauge is based on the changes in electrical resistant as the strain changes.

Rosette Gauges

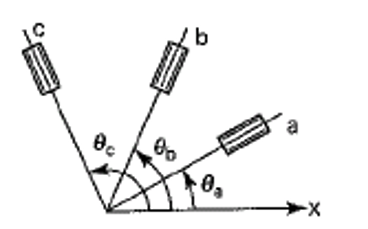

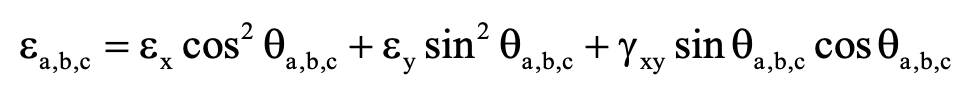

Let’s consider three strain gages bonded to a solid at angles θa, θb, and θc with respect to reference axis x:

Although a strain gage measures the change in length or the normal strain along its length, three gages with different orientations can be used to determine εx, εyand γxy using the transformation relations:

If the values of εa, ε b, and εc are measured for given gage orientations θa, θb, and θc, then εx, ε y, and εz can be obtained by solving the three simultaneous for the respective coefficients.

The arrangement of gages employed for this kind of measurements is known as a strain rosette.

Axial Gauges

Instead of rosette gauges, which measures three forms of stress on one plane, there will be cases when only axial displacement is measured.

In this case we will use axial gauges to measure displacement.

The benefit of axial gauges is such that there will be less to connect to a data acquisition system because we’re only measuring displacement in one direction vs. 3 for rosette gauges such as above.

Applications of Measuring Strain in Engineering

The design of structural mechanisms involve measuring stress and strain. The use of determining the stress and strain in a given structure upon loading conditions is extremely important.

We will bond strain gauges as discussed above to structures and perform mechanical testing of them to get results such as stress and strain data.

Static Test – Tensile Testing of a Specimen

This will be the most common form of mechanical testing done on an object both in academics and in the industry.

Academic

In an academic setting for engineering, you will be taking a lab class in which you will perform tensile testing on an simple object. You will be pulling an object at a certain load value until it fails. You will then be taking the test data and incorporating data such as stress-strain curves to plot your reports.

Industry

In the industry you will be doing the same thing, but the testing you are performing will be much more complicated. Instead of testing something simple such as a bar or a rod, you will be testing entire structures. Structures such as airplane wings, structural joints such as I-beams, pressure vessels and a lot more fun stuff.

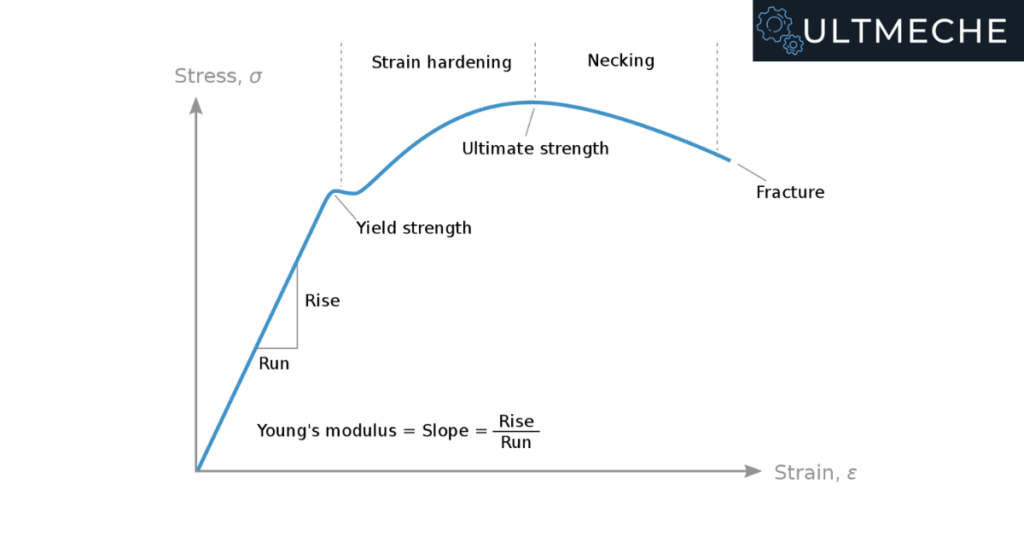

Stress Strain Curve

The data that we want from mechanical testing of a specimen will be the stress strain curve:

The stress is calculated by dividing the load over the cross sectional area. (See what is stress in engineering)

When performing mechanical testing for a company or a customer, this is the data that companies will be spending thousands of dollars on.

Your job as an engineer in the industry is to contribute so that we can get this data.

By giving this data to the customer, we know whether or not an engineering system will work or not, in real time.

If you’re interviewing for an engineering internship or an entry level engineering position you will likely need to explain this mechanism.

Check out: Structural Engineering Interview Questions and Strength of Materials Interview Questions – Top 23

Strain in Engineering Classes Example Problems

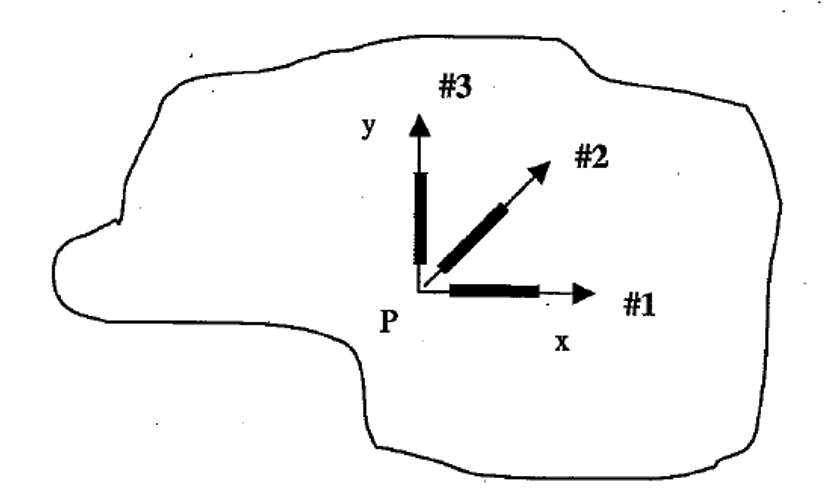

Let’s take a look at a strain problem of an aluminum alloy plate with strain rosettes.

A thin aluminum plate is loaded under plane stress conditions. The strains at a given point P on the plate were measured by a 45˚ rosette to be (1, 3, 7) × 10-5. the Young’s modulus and Poisson’s ratio of aluminum are 107 psi and 0.3 respectively.

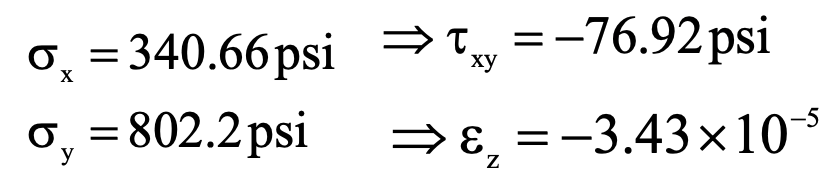

Determine the stress components σx, σy, τxy and the strain component εz at P.

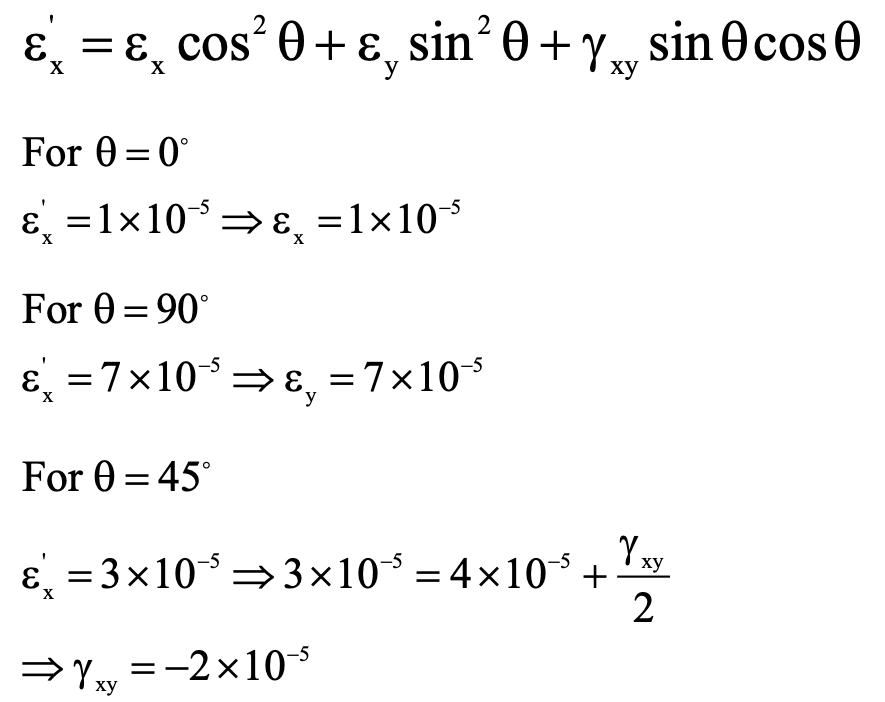

If we take a look at the strain equation above for rosette gauges,

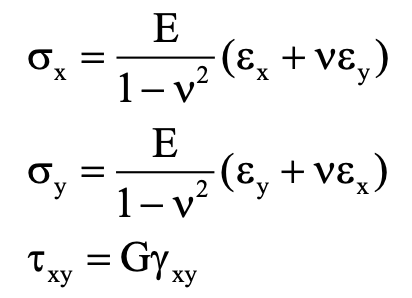

Let’s then use strain relations for plane stress to get the stress components:

We then use the values of εx, and εy from the previous slide to obtain the stresses:

Closing Thoughts on Strain in Engineering

If there’s anything to take away from this is that strain represents elongation over the total length. This elongation gives us as engineers an idea of how the material will behave given loading conditions.

Engineering companies are responsible for the design of structures and mechanisms that need to withstand certain loading conditions.

We as engineers are responsible for providing submittals such as documentation, reports, charts, graph, and data to the customer.

FAQ – What is strain in engineering?

Yes! Strain is 100% important to understand in engineering as it tells us the behavior of a material upon loading. Almost all materials and components designed and delivered by companies will be subject to loading conditions.

The formula for strain is elongation divided by the total length

About the author

Kazuyoshi Fujimoto, PE

Founder | Engineering Career Coach | Principal Mechanical Engineer

Kazu oversees all of ultmeche’s engineering services. He provides consulting such as resume reviews, rewrites, mock interviews, and all services career related. Additionally, Kazu performs consulting work regarding Oil & Gas, Automotive, and Aerospace & Defense. Kazu is licensed as a professional engineer in the state of California and has 9+ years of experience in Oil & Gas, Automotive, and Aerospace & Defense.

2 thoughts on “What is Strain in Engineering?”