The formula for normal stress is σ = P/A

With the following variables:

- σ = Stress

- P = Force

- A = Area

In the industry, it will be important to know how to quickly calculate normal stress in mechanical design applications. This will be important in determining whether or not an application will be safe upon it’s operating conditions.

Although Finite Element Analysis is a very helpful tool to solve stress calculations for us, it will not mean anything if we do not understand what normal stress is and how we can simply calculate it.

You will also be put in situations where you will need to quickly calculate stresses to verify something on the fly.

March 2, 2024What is normal stress?

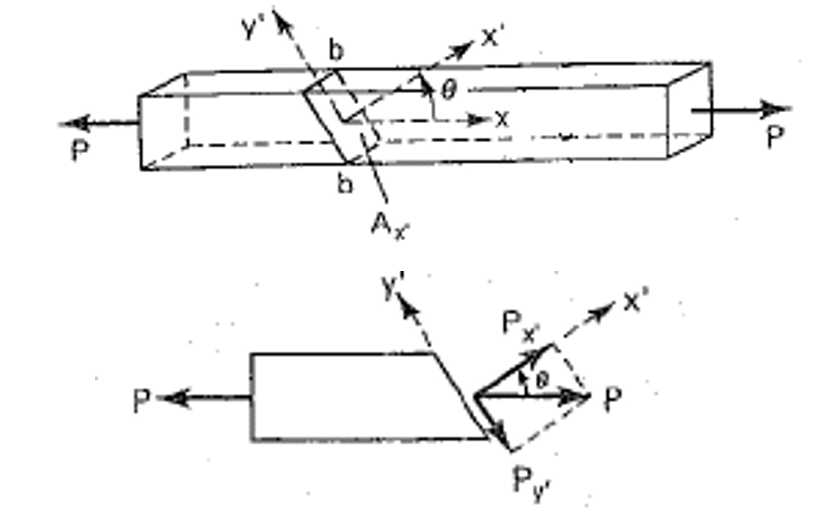

Let’s take into account the inclined plane of b-b of the forged metal bar in tension shown:

The normal axis is represented by x’, which is formed by angle θ and force P.

Through trigonometry, we break up the P force vector into the two components:

Uniaxial Stress Case Formulas

For a uniaxial stress case of the metallic bar above, we are able to represent the following using trigonometry:

The normal and shearing stresses, uniformly distributed over the slanted area Ax΄ = A/cosθ of the inclined plane are given by

σx΄ = Pcosθ / Ax΄ = σxcos2θ

τx΄y΄ = -Psinθ / Ax΄ = -σxsinθcosθ

Maximum normal stress formula

σx΄ is maximum when θ is 0º or 180º, and τx΄y΄ is maximum when θ is 45º or 135º.

Thus the formula for maximum normal and shear stresses for the uniaxial stress cases are:

σmax = σx

τmax = +/- (1/2)σx

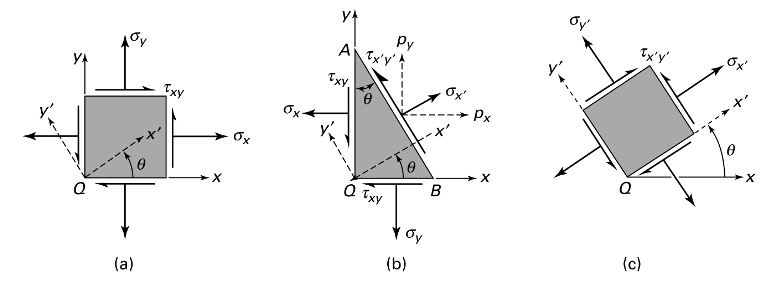

Plane Stress Transformations

To get the normal stress on any inclined surface of an object, we need to use methods of plane stress transformations.

These methods of plane stress transformation are how we determine what the respective normal stress is on the elements.

To see more on the breakdown of plane stress transformations, check out: What is Stress in Engineering?

Average normal stress formula

The average normal stress is represented by the average normal force divided by the cross sectional area.

For practical design purposes, we will only take into consideration what the average normal stress formula is.

The reason being that many mechanical systems will in actuality go through a large number of variable stresses.

As a result, for a quick calculation, we use the average normal stress formula to determine whether or not the system is good.

Allowable normal stress formula

In the mechanical and structural engineering industry, we use allowable limits to determine that the stresses on a system are acceptable.

Various types of criterion will be used to determine what the allowable limits on an engineering system are.

Allowable limits on stress will be based on parameters such as yield strength or normal strength of a material.

Standards for determining allowable stresses are also different.

A simple method of calculating allowable stress is to divide the yield strength of the material by the factor of safety.

For example, if we want a factor of safety of 2 for our pressure vessel, using ASTM A36 Steel, we will end up with 36,000 PSI / 2 = 18,000 psi for our allowable value.

What is a factor of safety?

The factor of safety (FOS) or safety factor (SF) is the ratio between what the allowable stress and either yield or ultimate tensile strength of a material.

A typical number used for factor of safety falls between 1~4 based on industry practices.

Different safety factors will be used for different types of applications so as a result, determining them will require being strategic.

You will need to refer to engineering standards to determine what are acceptable allowable values and factors of safety.

In the industry you do not want to over design a component because that will cost alot of money.

You won’t want to under design a component either because that will make it fail.

You want to be just right when designing and determining factors of safety.

Normal Stress Calculation Example

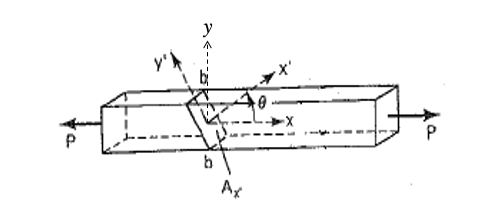

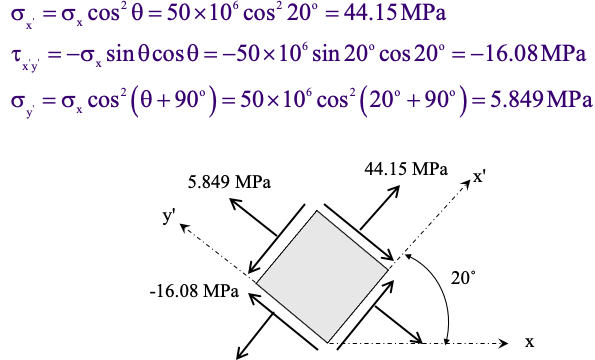

Prismatic Steel Bar Example

A prismatic steel bar of 50-mm by 50-mm square cross section is subjected to an axial tensile load of P = 125 kN

Calculate the normal and shearing stresses on all faces of an element oriented at θ = 20˚

The formula for normal stress is σx = P/A = 125 kN / (0.05 mm2) = 50 MPa

When we use this value for normal stress and using θ = 20 we will get:

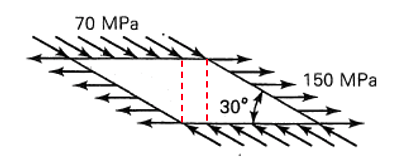

Thinly Skewed Plate Normal Stress Calculation Example

A thin skewed plate is subjected to a uniform distribution of stress along its side as shown in the figure below

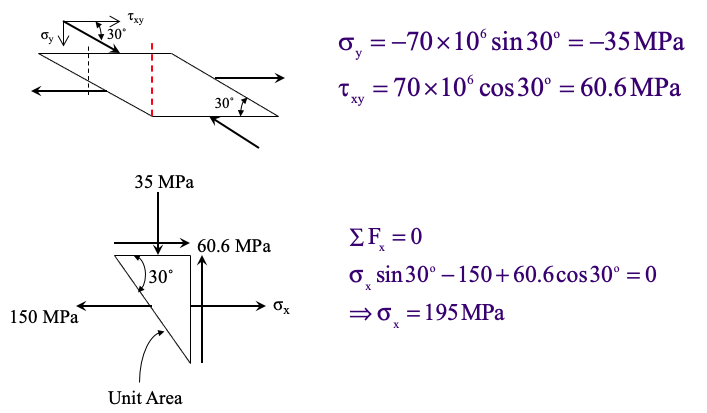

Calculate (a) the normal stress σx, σy, and shear stress τxy, and (b) the principal stresses and their orientations.

To solve this problem we will need to perform stress transformation and use trigonometry to determine the resultant stresses.

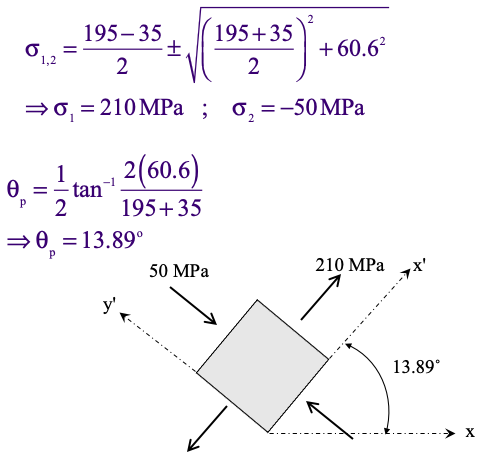

To solve for the principal stresses, we take the components we have just calculated and plug them into the principal stress formula.

For the principal stresses, we will get the following:

Closing

Stress in engineering is a very complicated subject matter because there are many components to understand.

Normal stress, shear stress, allowable stress, tensile stress, compressive stress are some example to name a few.

Although solving for normal stress is easy, it gets difficult when incorporating complex geometry in systems.

To solve these problems in a strength of materials class, mechanical intuition and aptitude is a must.

The math skills needed to do well in classes such as these will also compound such as trigonometry.

Even basic skills such as drawing free body diagrams of systems from physics classes will come into play.

As a result, this is why classes such as physics, statics, and dynamics are prerequisites for strength of materials classes.

Strength of materials is one of the most important classes as a mechanical engineer, so make sure you understand at least the basic concepts.

Check out: Strength of Materials

What is Stress in Engineering – Video

For a video explanation on going over what is stress in engineering see below:

About the author

Kazuyoshi Fujimoto, PE

Founder | Engineering Career Coach | Principal Mechanical Engineer

Kazu oversees all of ultmeche’s engineering services. He provides consulting such as resume reviews, rewrites, mock interviews, and all services career related. Additionally, Kazu performs consulting work regarding Oil & Gas, Automotive, and Aerospace & Defense. Kazu is licensed as a professional engineer in the state of California and has 9+ years of experience in Oil & Gas, Automotive, and Aerospace & Defense.

1 thought on “Normal Stress Formula”